minimum thickness for durometer test|durometric hardness test : factory Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. The test measures the penetration of a specified indentor into the material under . webCreate a warm welcome and cozy atmosphere with nibbles like spicy keto roasted nuts, keto mummy dogs, and low carb onion rings. Look below for more tantalizing game openers. Keto BLT with cloud bread. 7 g. Keto hot dog buns. g. Bacon-wrapped halloumi cheese. Guacamole. 5 g.

{plog:ftitle_list}

Data de lançamento: 15 de dezembro de 2022. Género: Ação/Aventura, Fantasia, Ficção Científica. Avatar: O Caminho Da Água alcança novos patamares e explora profundezas desconhecidas no regresso de James Cameron ao mundo de Pandora neste filme de aventura e ação repleto de emoções. Mais de uma década após os acontecimentos do .

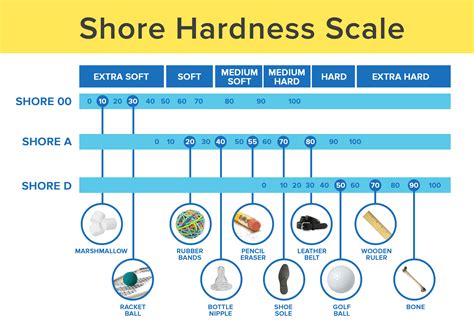

Durometer scale to use: The most commonly used durometer scales are “A” and “B.” These two scales combined cover the hardnesses of rubbers to nylons. .Durometer Hardness is used to determine the relative hardness of soft materials, usually plastic or rubber. The test measures the penetration of a specified indentor into the material under . The ASTM D2240 standard outlines the test procedure for measuring the hardness of elastomers using a durometer. The test involves measuring the depth of penetration of a . 1.1 This test method covers twelve types of rubber hardness measurement devices known as durometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. The .

Shore A durometer is appropriate for measuring the hardness of specimens that are flat, parallel, and of a certain minimum thickness. ASTM and ISO each specify different minimum thicknesses: ASTM D-2240 Type A . 1.25 mm (0.050 in.) or greater, although specimens of lesser dimensions may be successfully accommodated under the conditions specified in Section 6, and have a Type M .

The standard test specimen for most durometer types has a minimum thickness requirement of 6 mm. The specimen should also have flat, parallel surfaces that are at least 24 mm in diameter. .Durometer hardness is dependent on the elastic modulus and viscoelastic behavior of the material being tested. Inferences are often drawn between durometer hardness and other physical characteristics of the material being .

The minimum distance of the test points must be maintained according to the standard. The center distance between the indentations should be ≥ 5mm and ≥ 12mm to the specimen edge.Identify the appropriate Shore hardness scale to measure your test material. Step 2. Place the sample on a flat, hard surface that is at least ¼’’ thick. Step 3. Holding the durometer firmly, place it on the test sample with the indenter .2. Whenever possible, the thickness of a sample should exceed 6 mm (approx. 0.250"). If the sample is thinner then this, then the sample can be backed with a sample of the same material to increase the thickness. 3. Test Coupons or .

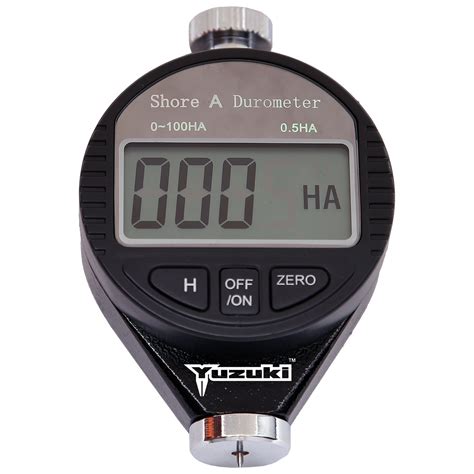

This Shore D durometer uses an impact rod with a 30º conical point and 50 Newtons (N) of force to make a surface indentation on material samples with a minimum thickness of 6 mm or 0.24 in. (Note: If a material sample does not .A durometer gauge or durometer tester is needed to perform a durometer hardness test procedure. Durometer devices determine the surface hardness of many different materials, including polymers and elastomers. . of force to .For accurate readings, the material under test should be at minimum 0.25" (6.4mm) thick. The Elcometer 3120 range of Shore Durometers are an easy-to-use solution for testing of material hardness, and have been the standard for hardness measurement since their invention by Albert Ferdinand Shore in 1924.

Type M durometer is intended for use on specimens having a minimum thickness of 0.050 inches, although it can be used on thinner specimens if there is data supporting the accuracy of the measurement. There are several standard testing methods that exist for measuring rubber durometer. ASTM D-2240 and ISO 868 are two of the most common.%PDF-1.4 %âãÏÓ 1 0 obj /FormType 1 /Subtype /Form /Resources /Font /R8 2 0 R /Ft1 3 0 R >> /ProcSet [/PDF /Text] /ExtGState 4 0 R >> /Type /XObject /BBox [0 0 595 839] /Filter /FlateDecode /Length 283 /Matrix [1 0 0 1 0 0] >> stream xœu MoÂ0 †ïù ïmô ñ± lš4¦}äØK–˜¶¨MJšlb¿~ ²Ó„,Ë’í×ïã Ò!GzŠKU ½ÏPt,ÅcÌ‚ ?/àRTƒLÄ¥ù©!v¬×qÜrÌ cˆ† ˆ=Û ö ƒõ .

Minimum Thickness Requirements Product Data Sheet PDS-THK-2010 March 2010 Minimum allowable thickness for a corresponding hardness in the respective scale Minimum Minimum Thickness Thickness Regular Rockwell Superfical Rockwell inch mm C A B 15N 30N 45N 15T 30T 45T 0.006 0.15 - - - 92 - - - - - .

The two standards are very similar for each corresponding type of hardness test but have small differences between them for details such as the minimum thickness of the sample. The common ASTM and ISO standards for the four most popular hardness tests in metallic materials are listed below: Durometer is a standard in industry for measuring the hardness (or indirectly, modulus) of a material; A common way of measuring hardness of plastics is through Shore durometer testing ; . The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into . Significance and Use 4.1 This test method is based on the penetration of a specific type of indentor when forced into the material under specified conditions. The indentation hardness is inversely related to the penetration and is dependent on the elastic . Standard Test Method for Rubber Property—Durometer Hardness D2240-15R21 ASTM|D2240 .

rubber durometer hardness

Fully Automatic Durometer – Digi Test II is a modularized tester for Shore, IRHD and VLRH. To find out more about this product, contact Bareiss North America. . Minimum material thickness [mm] Shore A soft rubber, elastomers, natural rubber products, neoprene, casting resin, polyester, soft PVC, leather, pressure rollers, etc .

The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact measurement points to how much force a material can handle before an indent is created.Minimum Sample Thickness-Type A = 6.35 mm (0.250") Minimum Sample Thickness-Type M = 1.25 mm (0.050") CE Marked, RoHS Compliant; Portable Battery-Powered Printer for Hardcopy Documentation. . Durometer Test Stand for RX Series Durometers. ,495.00. Add. RX-CLW-C .The Jominy test, also known as the End-quench test, is a standardised method for determining the hardenability of steel in accordance with ISO 642 and ASTM A255. The hardenability describes the ability of the steel to increase the hardness at the surface or throughout the workpiece by forming martensite or bainite.

3. Place test block on the steel surface. Put Durometer on top of the test block and push the needle down through center hole on test block until Durometer foot surface gets fully contact with test block. It should read ± 1 Shore as per the value mentioned on test block. 4. Please hold Durometer firm and perpendicular to testing material.

Standard Test Method for Rubber Property—Durometer Hardness1 . D374 Test Methods for Thickness of Solid Electrical Insu-lation (Metric) D0374_D0374M D618 Practice for Conditioning Plastics for Testing . with the center a minimum of 6.0 mm (0.24 in.) from any edge of the foot. When the presser foot is not ofThis Shore D durometer uses an impact rod with a 30º conical point and 50 Newtons (N) of force to make a surface indentation on material samples with a minimum thickness of 6 mm or 0.24 in. (Note: If a material sample does not meet the minimum thickness required, the sample should be reinforced on the back with more of the same material.) This test method is not equivalent to other indentation hardness methods and instrument types, specifically those described in Test Method D1415. This test method is not applicable to the testing of coated fabrics. To test for Shore D durometer, a 44.5 N force is applied onto a material using a 30° conical head. . Additionally, ensure that samples meet the minimum thickness requirements—typically at least 6 mm—to avoid skewed results due to inadequate material thickness for proper indentation. Apply proper testing technique: .

The conditions are specifically defined in ASTM D2240. In general terms, it outlines the preparation and configuration of the test specimen as well as the details of performing the durometer hardness test. Note: ASTM D2240 may be found in Volume 09.01 of the American Society for Testing and Materials“Annual Book of ASTM Standards.” CCSi .Analog Ergo Style Durometer ASTM Type A Model 408 • Accuracy ±1 Point • ase Tapers to 1”x 1” • Max Hold Pointer Standard • A2LA/NIST ertification Available • Easy to Read 0 to 100 Point Dial • Accessory Test Stands Available • Each Instrument is Individually alibrated • Meets or Exceeds urrent ASTM D2240 Specifications for Type A • Includes Aluminum Test lock and Sturdy .

What is the minimum thickness of material necessary to measure with the PosiTector ® SHD? According to ASTM D2240-15 “Standard Test Method for rubber Property – Durometer Hardness”, the test specimen must be at least 6.0 mm (0.24 inches) thick unless it is known that equivalent test results can be obtained with a thinner specimen.

The size of the specimen used for the test is generally 6.4mm (¼ in) thick. It is possible to stack several specimens to achieve this thickness, but one specimen is preferred for accuracy. The durometer hardness test results are reported in either Shore A or Shore D scales, depending on the type of material being tested. USA Testing Lab for ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness in USA, Indonesia, Philippines, Malaysia, Thailand, Canada, China, India, and all over the World. (302)244-7710 . . The test specimens typically have a thickness of .

hardness test for rubber

The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless quantity. It goes between 0 and 100. The higher number of hardness represents the harder material.

thickness of 0,25 in. (6 mm.). Always use standard hardness discs 1.28 in. diam. by 0,25 in. thick (ø32 x6 mm.), or 6 in.x 6 in.x 0.075 in. (150x150x2 mm.) sheets piled up to a minimum of 0,25 in. (6 mm.) to determine durometer hardness. It has been almost impossible to obtain reliable and reproducible hardness readings on The Shore A hardness (durometer) scale is one of many durometer scales used to measure material hardness. Shore A durometers range from 0 to 100 — the higher the durometer value, the harder the material. The Shore A scale is often used in the polymer industry to aid in material selection, ensure consistent quality products, and easily compare .

557K Followers, 1,142 Following, 2,048 Posts - See Instagram photos and videos from Cristina Ranzolin (@cristinaranzolin)

minimum thickness for durometer test|durometric hardness test